How can we feed the world of tomorrow?

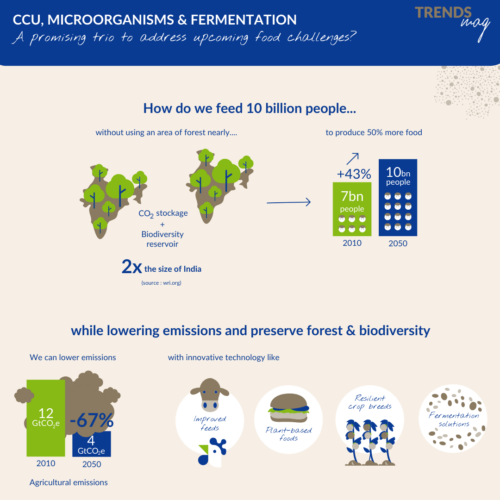

According to the World Resource Institute, we will need to feed 10 billion people by 2050. To do this, food production will have to be increased by 56%, which could require an expansion of cultivated land equivalent to 2 times the size of India.

Yet we know that such an expansion of agricultural land would be to the detriment of natural ecosystems, which provide essential services such as climate and water regulation, soil stabilisation, biodiversity and CO2 capture (see article Microorganisms & climate change – TrendsMag).

At the same time, we urgently need to reduce our greenhouse gas emissions considerably before 2050 if we want to limit global warming as much as possible.

Agriculture is a sustainable and essential means of producing human food, but its expansion is limited by the need not to use more land to combat global warming. Indeed, destroying the critical forests such as the ones present in Brazil, Indonesia or Africa, which are veritable natural carbon sinks, would be to the detriment of greenhouse gas emissions.

To meet tomorrow’s food and climate challenges, we need to find complementary solutions.

One of the levers for action: Carbon Capture and Use

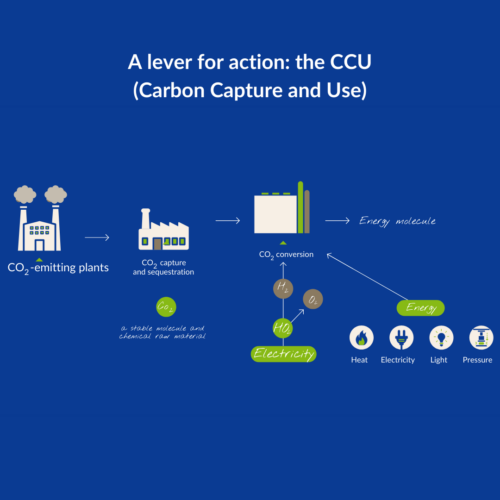

One of the key methods of tomorrow could be CCU (Carbon Capture and Use), i.e. the capture and use of CO2 from the atmosphere, the sea or industrial effluents. Recycling CO2 into value-added products represents a real opportunity to tackle environmental problems and achieve a circular economy.

CCU could make it possible to create sustainable alternatives to the fossil carbon-based compounds on which our society currently depends. Fossil fuels are mainly used for energy purposes, but they are also a source of essential carbon that is used massively in the production of chemical compounds and construction materials used in our daily lives. The development of a CCU based industry could offer a way of maintaining our current quality of life without relying on oil extraction.

What is Carbon Capture and Use?

CCU involves tackling the main cause of climate change: CO2. This greenhouse gas can be captured and then transformed into more complex carbon molecules to serve as a source of carbon or energy.

However, CO2 molecules are stable molecules and therefore require a significant input of energy to be transformed. This energy is generally supplied in the form of heat, electricity and/or light. A catalyst is commonly used to lower the energy barrier and speed up the reaction.

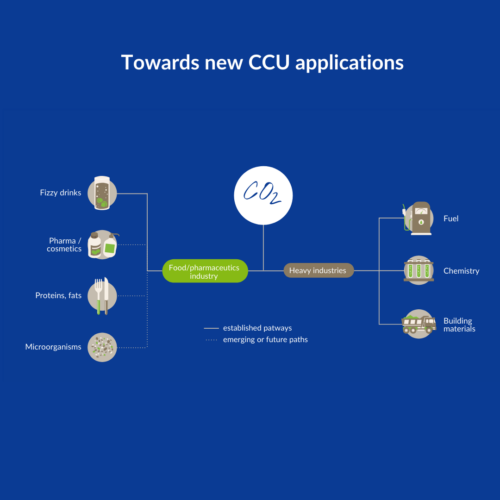

At present, CCU is mainly being developed for high-carbon-emitting industries such as cement production, steelmaking, shipping and aviation. However, as the technology advances, less carbon-intensive sectors such as pharmaceuticals and food production could soon benefit from it.

Carbon Capture and Use and the potential of microorganisms: two levers for the future of food production

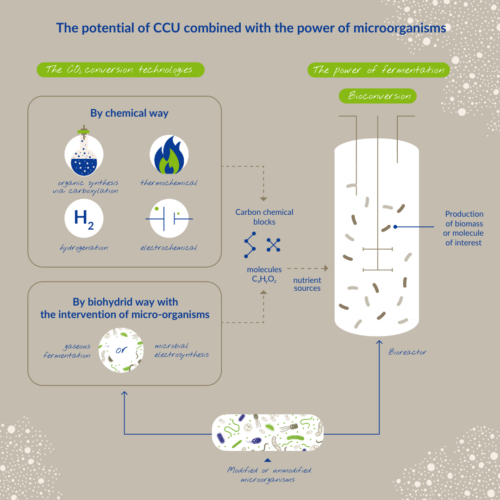

The transformation of CO2 into carbonaceous molecules of interest in a more energy-rich state is based on the reduction of carbon through the formation of carbon-carbon, carbon-nitrogen or carbon-hydrogen bonds, using energy and often catalysts (iron, cobalt, non-precious metals).

Traditionally, the process of converting CO2 involves chemical and biochemical processes. The strategies envisaged may involve a wide range of techniques, including organic synthesis via carboxylation, hydrogenation, electrolysis, and thermochemistry.

In parallel, the integration of biological systems, in particular micro-organisms, offers a new ecological way of improving the efficiency and applicability of CCU technologies.

Scientists are particularly interested in designing innovative methods for fixing CO2 using microbial cell factories, capable of synthesizing precursors of crucial substrates with the inherent capacity to serve as bio-fabrication substrates in numerous processes. These microbial factories also offer an environmentally-friendly alternative to conventional industrial procedures. Microbial Electrochemical Technologies (METs) are of particular interest because they exploit the interactions between micro-organisms and electrodes to convert the chemical energy of organic compounds into electricity or to produce useful chemical compounds.

Microbial electrosynthesis (MES) is a type of MET that can use CO2 to produce chemicals and fuels using micro-organisms as catalysts and renewable electricity as an energy source. The latest research suggests that this technique is promising for the conversion of CO2 into carbon compounds (C1 & C2) or even multi-carbon compounds useful in the field of human & animal nutrition & health.

Thanks to the potential of micro-organisms and advances in genetic engineering, CO2 could be considered a raw material in its own right for the production of food ingredients. It offers complementary services with agriculture, as it does not require arable land.

Imitating the natural process of fixing CO2 to produce alcools, lipids or other organic materials could potentially revolutionize the food sector, reshape the bioeconomy, preserve biodiversity and minimize the carbon footprint.

Legend: As an alternative to chemical processes, microbial electrolysis or gaseous fermentation, powered by renewable electricity, can be used to convert CO2 into a substrate consumed during the fermentation of micro-organisms in a bioreactor, ultimately producing microbial biomass or compounds of interest.

New applications of Carbon Capture and Use

Today, the field of CCU is still emerging, with new companies and researchers finding applications for it every year. Some are already well advanced, with companies such as Lanzatech, which supplies aircraft fuel made from captured carbon, Carbon Cure, which traps carbon in building materials, and the Flue2Chem consortium, which is working on replacing cleaning agents traditionally made from petroleum.

Other companies keen to further develop the circularity and sustainability of their processes and/or to preserve agricultural resources are adopting the CCU.

Coca-Cola, for example, has begun to use captured CO2 to carbonate some of its sparkling water brands. Numerous start-ups are appearing in food production, such as SolarFoods, which offers proteins, and Circe, which is devising a new way of producing lipids, both are exploiting this combination of micro-organisms and CCU. In the pharmaceutical and medical sectors, it could be used to produce ectoin and hydroxyectoin (€1,000-1200/kg). At present, microbial production of ectoin is based on sugar fermentation, but manufacturers are hoping to extend this to other more sustainable and less expensive substrates.

Recent research in the field of CCU shows immense potential for developing sustainable and efficient food production methods with the support of fermentation and micro-organisms.

As a biotech company with extensive knowledge and expertise in fermentation, Lesaffre could be one of the future UCD players in the food industry.

How could Lesaffre implement Carbon Capture and Use technology?

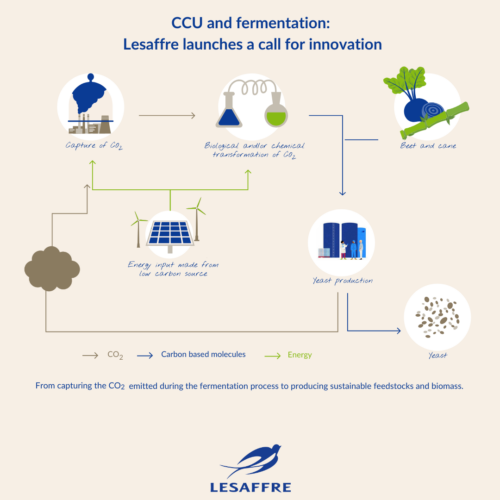

In order to be produced, yeast needs a source of nutrient. This nutrient source is usually an agricultural by-product that provides both carbon and energy in the form of sugar, which we use to grow and multiply micro-organisms. During the natural fermentation process, the yeast releases some of the carbon naturally supplied in the form of CO2. Why shouldn’t yeast producers consider this biogenic carbon dioxide (produced by the yeast’s metabolism) as a resource and not as “waste”?

Lesaffre has recognized expertise in fermentation, a remarkable collection of micro-organisms, and benefits from industrial fermentation capacity on a global scale. Micro-organisms have a very rich metabolic potential which enables them to transform simple molecules into a wide range of complex and natural products. Many of them can be grown on simple media. As such, if we managed to produce nutrient sources via CCU, we would open up new pathways for sustainable food development.

To be relevant and effective, these new processes will have to be technically feasible, economically viable and deliver the same or even higher level of environmental and social benefits than existing processes.

This challenge is complex and will require new partnerships throughout the value chain, involving technology providers, manufacturers, end-users, researchers, policy-makers and consumers. Lesaffre’s RD&I and Operational Management teams firmly believe in the power of collective intelligence and open innovation. This is why, last March, the Group launched a call for innovation to discover new avenues of innovation in the field of carbon capture and utilization (CCU) specifically adapted to the food industry.

“At Lesaffre we are committed to exploring innovative ways to help tackle the major food, health, and environmental challenges that the world faces. We acknowledge that the challenge of climate change is immense and believe that fermentation and microorganisms are part of the solutions; We are convinced collaboration will be key to finding solutions. That’s why, relying on our expertise in fermentation, we’re seeking to lead joint initiatives and to work with partners from across the industry to develop innovative approaches to carbon reduction and sustainable production. By joining forces with SoScience and experts in this call to open research, we are once again affirming our desire to work together to better nourish and protect the planet,” declares Brice-Audren Riché, CEO of Lesaffre.

Researchers, experts and technology suppliers, if you are interested in this pioneering initiative, do not hesitate to submit your proposals via the dedicated SoScience open innovation platform (until June 24), and then after this date to send an e-mail to the following address ComGroupe@lesaffre.com

Sources

- WRR Report: https://www.wri.org/insights/how-sustainably-feed-10-billion-people-2050-21-charts

- More information on CCU and the impact it could have on Europe’s transition to climate neutrality – https://co2value.eu/wp-content/uploads/2024/01/FINAL-LAYOUT_CVEs-EU-Roadmap-for-CCU-by-2050.pdf

- Tingting Zheng, Menglu Zhang, Lianghuan Wu and al. (2022). Upcycling CO2 into energy-rich long-chain compounds via electrochemical and metabolic engineering. Nature Catalysis 5(5):1-9. https://doi.org/10.1038/s41929-022-00775-6

- Congqiang Zhang, Christoph Ottenheim, Melanie Weingarten and LiangHui Ji. (2022). Microbial Utilization of Next-Generation Feedstocks for the Biomanufacturing of Value-Added Chemicals and Food Ingredients. Front. Bioeng. Biotechnol., 11 April 2022Sec. Industrial Biotechnology. Volume 10 – 2022. https://doi.org/10.3389/fbioe.2022.874612

- Yee Ho Chai & al. Basic principles of CO2 capture and conversion technologies. Nanomaterials for Carbon Dioxide Capture and Conversion Technologies-Micro and Nano Technologies-2023, Pages 25-6. https://doi.org/10.1016/B978-0-323-89851-5.00006-8

- Kurt, E.; Qin, J.; Williams, A.; Zhao, Y.; Xie, D. Perspectives for Using CO2 as a Feedstock for Biomanufacturing of Fuels and Chemicals. Bioengineering 2023, 10, 1357. https://doi.org/10.3390/bioengineering10121357

- RCI’s scientific background paper: “Making a case for Carbon Capture and Utilisation (CCU) – It is much more than just a carbon removal technology” (July 2023) – https://renewable-carbon.eu/publications/product/making-a-case-for-carbon-capture-and-utilisation-ccu-it-is-much-more-than-just-a-carbon-removal-technology/

- Coca-cola uses carbon capture to manufacture its soft drinks

- https://www.businessgreen.com/news/4187546/bottling-coca-cola-trial-direct-air-captured-carbon-soft-drinks#:~:text=Coca%2DCola%20pourrait%20bientôt%20remplacer,(DAC)%20technologie%20développeur%20Airhive.

- Use of CCU in pharmaceuticals and cosmetics

- Sara Cantera, Diana Z. Sousa, Irene Sanchez-Andrea. Enhanced ectoines production by carbon dioxide capture: A step further towards circular economy. Journal pf CO2 Utilization. Vol 61, July 2022, 102009. https://doi.org/10.1016/j.jcou.2022.102009

- Givaudan announces collaboration with Lanzatech to develop sustainable fragrances using CCU – https://lanzatech.com/givaudan-and-lanzatech-announce-their-collaboration-on-developing-new-sustainable-fragrance-ingredients-from-renewable-carbon/

- https://www.givaudan.com/sustainability/2023-earth-day

- Publication on the general topic of converting CO2 into carbohydrate

Casey P. O’Brien, Madelynn J. Watson et Alexander W. Dowling

Challenges and opportunities in the conversion of CO2 to carbohydrates. ACS Energy Letters 2022 7 (10), 3509-3523. DOI: 10.1021/acsenergylett.2c01550