How can we feed a growing population in constant demand for better quality food? In the past, intensive livestock farming, the introduction of pesticides and the systematic use of antibiotics on animals have helped us meet this challenge. Today, these advances are being called into question from an environmental and animal welfare point of view. The finger is pointed at industrial agriculture, which is accused of being

responsible for greenhouse gas emissions, habitat destruction and the loss of wild animals, soil degradation, overexploitation of land and water, climate disruption… And past solutions are no longer sufficient to feed the planet. Global meat production, which has quadrupled since 1961¹ , has now reached its breaking point.

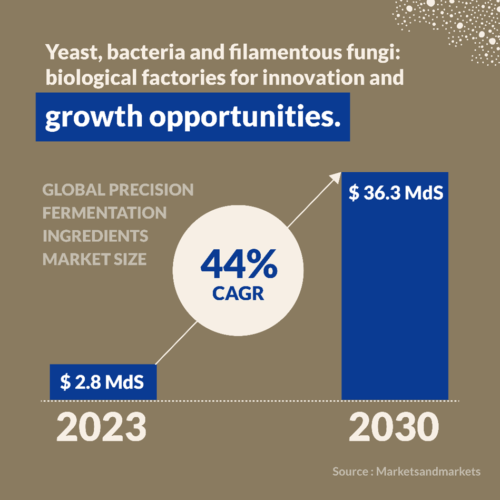

Faced with this situation and consumer demand, food manufacturers are looking to develop environmentally-friendly alternatives to protein sources. And more and more of them are turning their attention to precision fermentation.

From tradition to precision

This recent technology is based on traditional fermentation, an age-old know-how used to improve food preservation and nutritional value. Traditional fermentation can use micro-organisms naturally present on a substrate (support), such as yeast on grapes. It can also be better controlled by using a yeast starter, or resorting to repotting, a fermentation technique in which a small quantity of the previous fermentate is used to inoculate a new substrate. Traditional fermentation is responsible for many foods: bread, beer, wine, cheese, soy sauce, Korean kimchi…

Traditional fermentation has adopted industrial methods to produce molecules of interest such as enzymes, with applications in the food and health industries (probiotics, vitamins, etc.).

Improving the taste of vegetarian substitutes

In the protein alternatives sector, fermentation enables the production of micro-organisms designed to improve the taste of an ingredient derived from plants. This is what Biospringer by Lesaffre offers, producing a range of yeast extracts designed to improve the taste and organoleptic properties of animal protein alternatives.

Another modern technique based on fermentation is biomass fermentation. This produces large quantities of edible micro-organisms (yeast, bacteria, filamentous fungi, etc.), used as alternatives to the food sources produced by traditional agriculture. These micro-organisms can be consumed directly or used as functional ingredients: polysaccharides, proteins, lipids, omega 3 fatty acids, vitamins, minerals, dietary fibers…

Fermentation is now capable of improving the yield of food production, increasing the variety of food products, and creating new products from non-food biomass. Its potential impact on environmental protection is far from negligible. A recent study shows that replacing just 20% of the world’s consumption of beef and other pasture-raised livestock with proteins derived from fermentation could halve annual deforestation by 2050².

A method with great potential

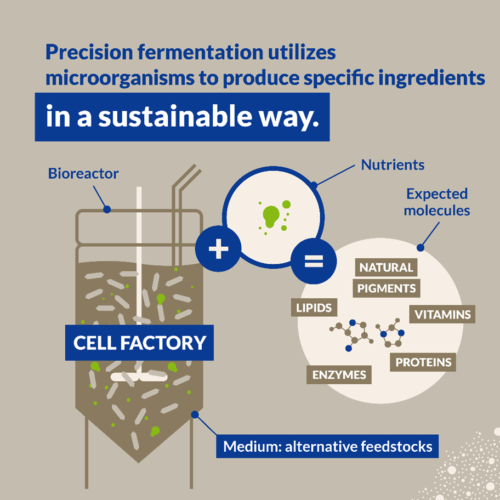

The latest major development in the world of fermentation is precision fermentation, which is already part of the fourth industrial revolution for the food industry. Precision fermentation makes it possible to produce specific compounds from renewable raw materials, with possible applications in sectors as varied as food, chemicals, medicine and cosmetics. In practice, precision fermentation uses micro-organisms as “cell factories”. Selected micro-organisms, placed in a bioreactor and fed a nutrient, secrete the desired molecule. Proteins, enzymes, flavoring agents, vitamins, natural pigments, fats… Many substances can be produced in this way, with a composition identical to the original products, without animal exploitation and with low environmental impact. Precision fermentation creates little or no by-products. In these “cell factories”, all resources are reallocated to produce only the desired compounds.

A relatively recent process, precision fermentation has already produced some major successes. Insulin, used in the treatment of diabetes and initially derived from animals, has been manufactured by precision fermentation since the 1980s. The same applies to chymosin. This enzyme, produced by cells in the calf’s stomach and used to make rennet for cheese, has been manufactured by precision fermentation since the 1990s.

The contribution of genomics

Precision fermentation is based on a thorough understanding of the microbes involved in the fermentation process and their metabolic capacities. Today, it is supported by recent scientific advances based on the study of genomes and synthetic biology.

Genomics uses high-throughput sequencing to analyze microbial communities in fermented foods and identify desirable strains and characteristics. The combination of genomics and synthetic biology makes it possible to design precise characteristics. Precision fermentation makes use of a range of fast-growing technologies: artificial intelligence, bioinformatics, systems biology and computational biology.

Animal proteins without livestock

Numerous start-ups and larger companies specializing in nutrition, chemicals or pharmaceuticals are already involved in precision fermentation. Many are working on the production of alternative proteins. They are succeeding in reproducing fats such as the fatty acid that gives meat its distinctive taste, omega 3 fatty acids from algae, and even palm oil, the current exploitation of which is responsible for significant deforestation. Among the food ingredients derived from precision fermentation already on the market are steviol glycosides (sweeteners), colorants and flavors for meat alternatives, egg alternatives, and milk proteins for the production of dairy substitutes. These companies also aim to produce functional ingredients: prebiotics, postbiotics, vitamins…

Food supplements and cosmetics

Food supplement manufacturers are also looking for safe, virtuous and sustainable production processes for their molecules of interest. For them, Gnosis by Lesaffre now produces by fermentation the purest form of salidroside, a bioactive component of growing popularity and derived from an over-exploited plant, Rhodiola rosea. Gnosis by Lesaffre also produces chondroitin by fermentation, a dietary supplement whose sourcing involves the exploitation of animals.

Cosmetics manufacturers, under pressure from consumers who wish to avoid petrochemical-based ingredients whose exploitation depletes ecosystems, are also investing in precision fermentation. Their objective: to produce plant oils, pigments, minerals and organic acids while limiting the exploitation of natural resources.

To keep environmental impact to a minimum and production costs down, the processes used in precision fermentation are constantly being optimized. The ingredients produced are currently fed with nutrients derived from corn or sugar cane. These sources can, for example, be replaced by by-products from the food industry, and short circuits can be set up. A constant search for better processes which, combined with the diversity of micro-organisms present on Earth and the continual advance of technologies, offers precision fermentation a promising future.

Notes :

¹ Food and Agriculture Organization of the United Nations (2023). Hannah Ritchie, Pablo Rosado and Max Roser (2019) – “Meat and Dairy Production” Published online at OurWorldinData.org.

² Humpenöder, F., Bodirsky, B.L., Weindl, I. et al. Projected environmental benefits of replacing beef with microbial protein. Nature 605, 90–96 (2022). https://doi.org/10.1038/s41586-022-04629-w

Sources :

Augustin, M. A., Hartley, C. J., Maloney, G., & Tyndall, S. (2023). Innovation in precision fermentation for food ingredients. Critical Reviews in Food Science and Nutrition, 64(18), 6218–6238. https://doi.org/10.1080/10408398.2023.2166014

Teng TS, Chin YL, Chai KF, Chen WN. Fermentation for future food systems: Precision fermentation can complement the scope and applications of traditional fermentation. EMBO Rep. 2021 May 5;22(5):e52680. doi: 10.15252/embr.202152680. Epub 2021 Apr 27. PMID: 33908143; PMCID: PMC8097352.