What is sustainable aviation fuel?

Sustainable aviation fuel (SAF) is a non-fossil fuel suitable for jet engines that has been certified as sustainable by independent third-party bodies. SAF can replace traditional fossil-based jet fuel (or kerosene), which is a blend of hydrocarbons. Sustainable fuels can be easily blended with jet kerosene without the need for any modifications to aircraft engines.

From production to jet engine combustion, SAF releases fewer CO2 emissions over its life cycle compared to conventional jet fuel. With a lower carbon footprint, SAF may play a key role in the decarbonisation of the aviation sector.

Blended SAF must meet the ASTM* D1655 standard specification, which provides guidelines on the safety and performance of fuels used in commercial aviation.

*ASTM International is a standards organisation that develops and delivers technical standards for materials, products, systems and services.

Sustainable aviation fuel production pathways

There are three main production pathways for SAF, each involving specific resources and technologies, with varying levels of maturity and environmental potential(1).

Biomass-based SAF

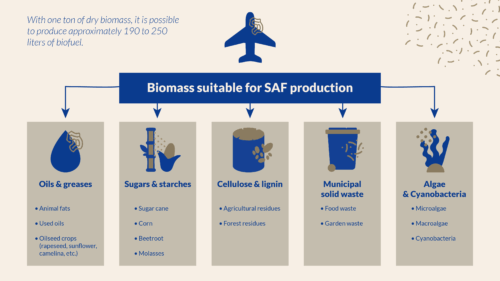

Biomass, defined as organic matter derived from plants and animals, provides potential sources of sustainable carbon for SAF, as well as high value-added chemicals and co-products.

Biomass-derived SAF(2) is produced using mature technology and is the most widely available type of SAF today.

It can be produced from lignocellulosic biomass (corn stalks, cereal straw, and other agricultural and forestry residues), starchy biomass, and sugar biomass (sugar cane and beet, molasses). Genetically modified or non-genetically modified microorganisms are capable of fermenting the sugars (glucose, fructose, sucrose…) present in these biomasses to produce bioethanol, isobutanol or butanol. Pretreatment and hydrolysis steps may be necessary to release the fermentable sugars from lignocellulosic biomasses. Bioethanol and butanol are then converted into aviation fuel via ATJ (Alcohol-To-Jet), a conversion process involving several steps: dehydration, oligomerization, and hydrogenation (HEFA process: Hydroprocessed Esters & Fatty Acids).

Numerous research projects are currently underway to exploit the potential of microorganisms in SAF production. And as indicated by the European-funded YAF (Yeast-based solutions for sustainable aviation fuels) research project, yeast can play a key role in the environmentally friendly production of economically viable SAF intermediates (terpenes or fatty acids (FAs)) from biowaste.

This type of SAF can also be made from waste cooking oil or animal fats from the food industry, which are converted into hydrocarbons compatible with aircraft engines through hydrogenation.

Finally, biomass-derived SAF can be produced from solid waste (agricultural, forestry, urban), which is converted into synthesis gas (syngas) and then into hydrocarbons.

Power-to-Liquid (e-fuels)

E-fuels are produced by combining carbon dioxide captured from the air or industrial emissions with green hydrogen extracted from water. The blend of CO2 and H2 forms a syngas, which is converted into liquid fuel and then refined to produce jet fuel.

Technology pathways for the production of e-fuels are currently under development. E-fuels offer some advantages: they are not derived from biomass and have a low carbon footprint since they are produced with the help of electricity generated from renewable sources (e.g. solar or wind power).

Advanced biofuels

Advanced biofuels include fuels derived from living organisms, such as microorganisms and algae optimized through biotechnologies such as synthetic biology. These fast-growing living organisms, such as yeast and microalgae, can be genetically modified to produce molecules similar to those found in kerosene.

Numerous research projects are currently underway to exploit the potential of microorganisms in SAF production. And as the European-funded YAF (Yeast-based solutions for sustainable aviation fuels) research project points out, “yeasts can play a key role in the environmentally friendly production of economically viable SAF intermediates, such as terpenes and lipids, from biowaste.”

Microalgae, meanwhile, produce oils that can then be converted into aviation fuel through hydrogenation.

Environmental and Economic Benefits of SAF

Sustainable aviation fuel is key to addressing the challenges of climate change and energy independence and is also a driver for economic growth in the aviation industry.

A lower carbon footprint

SAF has the potential to drastically reduce greenhouse gas emissions across its entire life cycle, from production to use, compared to fossil-based jet fuel.

Depending on the sources and production pathways used, SAF can currently cut CO2 emissions by up to 70-80% compared to traditional jet fuel, a figure that may reach 100% in the future with the improvement of production processes.

Reducing aviation’s reliance on fossil fuels

SAF can help the aviation industry to gradually reduce its dependency on crude oil, which is used to make jet fuel(3). This “green” fuel can be produced from a range of locally available, renewable feedstocks, such as agricultural waste and used cooking oil. SAF offers key benefits to the aviation sector, including reduced exposure to oil price fluctuations and enhanced energy security.

Positive economic outcomes

SAF technologies provide huge opportunities for economic growth, such as the development of new industrial sectors specialised in the production and processing of these new fuels and the creation of new jobs. Investments made in these innovative fuels also contribute to the development of various innovative projects to facilitate the aviation sector’s energy transition and provide a pathway to price stability and lower production costs in the long run. Future government-imposed penalties on carbon emissions will make SAF increasingly competitive compared to jet fuel.

Who is using SAF today?

Today, several airlines have already started using a blend of SAF and jet fuel to power their aircraft. Such efforts are encouraged by government incentive policies.

Airlines are leading the way

In 2008, Virgin Atlantic was the first airline company to test the use of SAF on a commercial flight. Since then, a number of other airlines have followed suit, using a blend of SAF and traditional jet fuel to power their commercial aircraft fleet. In 2016, United Airlines became the first airline company to introduce SAF into regular operations. In 2023, Virgin Atlantic became the first-ever commercial airline to operate a 100% SAF-fuelled commercial transatlantic flight.

For its part, Air France aims to incorporate at least 10% SAF globally by 2030. In 2024, the airline used 43,953 tons of SAF, avoiding the emission of more than 150,000 tons of CO₂.

Already, 43 airlines have committed to using approximately 16.25 billion liters of SAF by 2030.

Government regulations and incentives

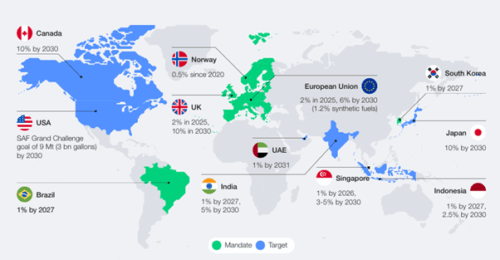

Several governments have introduced policies to encourage the decarbonation of the aviation industry and the development of sustainable aviation fuels. In 2022, the United States enacted the Inflation Reduction Act (IRA), allowing airlines using sustainable aviation fuels to benefit from three-year tax credits. The country encourages the use of SAFs in order to reduce aircraft fuel consumption by at least 30% by 2050. This incentive scheme supports the development of large-scale pilot projects across the aviation industry.

In 2023, the European Parliament introduced the ReFuelEU Aviation initiative. The regulation sets out mandatory SAF quotas for airport fuel suppliers, starting with a 2% SAF target in 2025. This figure is set to gradually increase to 70% by 2050.

The International Civil Aviation Organization (ICAO), which is responsible for coordinating global efforts to ensure a smooth transition to SAF, introduced the Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) to encourage the use of certified sustainable fuels as alternatives to carbon offsetting. Aircraft operators can purchase offset credits that meet the offsetting requirements notified by the State where they operate.

What are the challenges and obstacles to the adoption of SAF?

Despite recent improvements in fuel efficiency, aviation remains a major contributor to climate change. Accounting for 2.1% of all human-induced CO2 emissions and 12% of all transport-related emissions, the sector is already the world’s second biggest source of greenhouse gases. But what’s even more worrying is that, due to increasing demand for air travel, international aviation emissions are expected to triple by 2050.

If the world is to meet its ambitious climate goal of keeping global temperature rise to well below 2 degrees Celsius, the aviation sector must reduce its carbon footprint. However, as the World Economic Forum (WEF) correctly points out, it must do so without impacting the immense economic and social benefits that air travel provides: “The aviation industry has contributed significantly to realizing the benefits of globalization. Today, in this same context, it faces a major challenge: continuing to offer these benefits while adopting an environmentally responsible approach that involves its entire value chain.” The answer for striking this balance between sustainability and service is Sustainable Aviation Fuel (SAF).

SAF is a non-petroleum-based jet fuel produced by recycling sustainable raw materials or by using carbon that is extracted from plants. For example, SAF can be derived from agricultural waste, saw dust, or sewage. Even used cooking oil, which would normally be thrown away, can serve as a valuable raw material for making SAF.

“Sustainable aviation fuel is an alternative to the high pollution, high carbon emission sources that we use in aviation today,” says Marcelo Amaral, General Manager at Leaf. “With SAF, we have the opportunity to lower emissions while, at the same time, maintaining – even growing – a critical sector of the economy.”

Leaf by Lesaffre is a leading global player in developing the industrial biotechnology. This Lesaffre’s business unit develops industrial microorganisms and processes that allow renewable productions. In collaboration with players that are also passionate about accelerating the transition, Leaf designs and put into action high performance bio-based solutions.

These fermentation-based processes are now used to produce alternative fuels for aviation. With support from the BioEngineering Center of Excellence, Leaf is developing smart uses for biomass and microorganisms to develop new products or improved versions of traditional fossil-based products that are potentially more efficient and less toxic.

“Playing a key role in the production of the bio-renewable resources used by sustainable aviation fuels, fermentation will help drive SAF’s uptake and accelerate our progress towards a more sustainable aviation sector,” adds Marcelo Amaral.

Sustainable aviation fuel ready to fly

As Marcelo Amaral explains, flying on sustainable aviation fuel, including those derived from fermentation-based bio-renewable resources, reduces crude oil consumption and produces lower lifecycle carbon emissions compared to conventional jet fuel. “Over its lifecycle, SAF has an up to 80% smaller carbon footprint than traditional fossil-based jet fuel,” he says.

But beyond its potential to significantly reduce an aircraft’s emissions, SAF also features a higher energy density than traditional jet fuel. And, having undergone rigorous testing, SAF is already proven safe for use on commercial aircraft.

Unlike other alternative fuel sources (e.g., hydrogen, battery electric), SAF is certified as ‘drop-in’ or ‘ready-to-use’. In other words, it possesses similar properties, qualities, and characteristics as Jet A and Jet A1 fuel (the kerosine grade of fuel used by most turbine engine aircraft).

“This means aircraft using SAF perform the same as those operating with fossil-based fuels,” says Marcelo Amaral. “More so, using SAF does not require any modifications to the aircraft or additional ground infrastructure, so any aircraft can already fly with SAF today.”

The need for scale

By 2030, according to a report by the World Economic Forum (WEF), global demand for sustainable aviation fuel (SAF) is expected to reach 17 million tons per year (Mt/a), or 4-5% of total kerosene consumption. However, SAF production is lagging behind: to meet the likely demand in 2030, an additional production capacity of 5.8 Mt is needed(9).

In 2024, according to the European Union Aviation Safety Agency (EASA), SAF production accounted for only 0.53% of global kerosene consumption.

As can be seen, despite these advantages, the use of sustainable fuels remains low, with the main limiting factors being their lack of availability and high cost.

Due to limited supply, there is also a general lack of demand for SAF. Because demand and supply remain unbalanced, the cost of SAF is more than double the cost of conventional jet fuel – putting SAF far out of reach for many operators.

To make SAF economically viable, production must be significantly scaled up – something that fermentation could help with.

According to Marcelo Amaral, high performing industrial fermentation relies on advanced microorganisms and smart technical services. Leaf provides both products and process expertise across the globe, today for renewable bioethanol and advancing towards bio-sourced chemicals. For example, its unique Comprehensive Coupled Product and Process, or CP2, approach combines Leaf’s experience and recent advancements with investments in innovation and research.

“As SAF moves to commercial scale, Leaf is well-positioned to be the industrial fermentation partner for a sustainable tomorrow,” adds Marcelo Amaral. “And, as production of SAF ramps up, costs will go down and demand will increase – ultimately opening the door to the era of sustainable aviation.”

Towards the era of sustainable aviation

Helping accelerate the transition towards SAF are programmes like the Commercial Aviation Alternative Fuels Initiative (CAAFI). A public/private partnership between the aviation community and the Federal Aviation Administration (FAA), CAAFI’s goal is to promote the development of alternative jet fuel options that offer equivalent safety and favourable costs compared to petroleum-based jet fuel, while offering environmental improvement and energy supply security for aviation. The transition to SAF is also being driven by regulatory initiatives, as we have seen previously in Europe and the United States.

“All these initiatives and achievements highlight that SAF is the answer to aviation’s carbon challenge and the key to meeting the industry’s environmental goals,” concludes Marcelo Amaral. “SAF isn’t the future – it’s already here, now we just need to start using it.”

FAQ: Everything you need to know about SAF

-

Is SAF cheaper than traditional jet fuel?

No. SAF currently costs two to five times more than conventional jet fuel.

-

How can SAF help to reduce the aviation industry’s carbon footprint?

SAF releases fewer CO2 emissions during its production and combustion compared to regular jet fuel. European regulations, for example, require a minimum 65% reduction inCO2 emissions over their life cycle compared to kerosene.

-

What are the challenges hindering the widespread adoption of SAF?

Production costs remain high and production capacity is still limited. There are also logistical and technical complexities to overcome.

-

Can aircraft fly on 100% SAF?

Absolutely, some airlines have already operated flights on 100% SAF.

Sources:

- International Civil Aviation Organization & RessourceWise

- Air-journal.fr – Practical information: the different sustainable fuels used today in transport air

- World Economic Forum & Kearney report – Financing Sustainable Aviation Fuels (February 2025)

- ATAG – Beginner’s Guide to Sustainable Aviation Fuel

- org – Net zero 2050: sustainable aviation fuels

- Les Échos – Aviation: US tax break for green kerosene

- Le Monde – Air transport: Europe imposes a quota for sustainable fuels

- gouv.fr – Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA)

- weforum.org/publications/financing-sustainable-aviation-fuels-case-studies-and-implications-for-investment/